REASON:

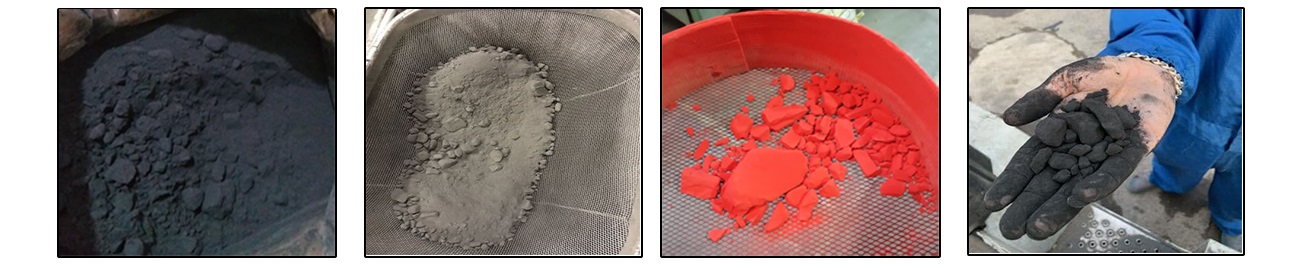

1- Unfavorable storage condition (High heat / humid area)

SOLUTION:

1-1- Check optimal powder storage conditions in technical data sheet

1-2- Sift the powder using sieve number 200-300 microns

REASON:

1- Air Pressure is too low or too high

2- Air channels of the flow plate are clogged

3- Powder is moist or is too fine

4- High temperature in the environment

5- Powder settled at the hopper bottom(old powder or poor storage conditions)

SOLUTION:

1-1- Control and adjust the air pressure

2-1- Empty the hopper, clean the pores of the fluidizing plate & if necessary replace the fluidizing plate

3-1- Check air for oil & moisture (Filters and Moisture Traps in the air system)

4-1- Control and decrease the temperature

5-1 - Stir the powder or sift it using sieve number 200-300 microns

REASON:

1- The powder quantity is more than 3/4th of hopper capacity

2- Oil or moisture in compressed Air

3- High temperature in the environment

4- Powder is moist or is too fine

SOLUTION:

1-1- Reduce powder quantity to 3/4th of the hopper capacity

2-1- Check air for oil & moisture (Filters and Moisture Traps in the air system)

3-1- Control and decrease the temperature

4-1- Use a fresh batch of powder

REASON:

1- The hopper air pressure is high

2- The powder quantity is more than 3/4th of hopper capacity

3- Powder is too fine

SOLUTION:

1-1- Reduce the hopper inlet air pressure

2-1- Reduce powder quantity to 3/4th of the hopper capacity

3-1- If the powder is new, you should contact the powder manufacturer

REASON:

1- Unnecessary excessive opening of the paint booth doors

2- Clogged filters inside the paint booth

3- Improper Spray Equipment

SOLUTION:

1-1- Keep the spray booth doors closed

2-1- Increase Spray booth ventilator suction

3-1- Change spraying nozzle type to a smaller or flat nozzle

REASON:

1- Air pressure is too low or too high compared to powder quantity

2- The air injector components are worn

3- Feed hose is too long or diameter is wrong

4- The powder is too fine

SOLUTION:

1-1- Reduce or increase the pressure according to powder quantity

2-1- Control and Replace nozzle

3-1- Adjust the length and the diameter of the hose appropriate for the powder flow

4-1- increase the air pressure and decrease the powder amount in hoses

REASON:

- Poor grounding

- the distance between the gun and the part is too much

- parts are placed too close to each other

- Powder is too coarse

- line speed is too high

SOLUTION:

- Check and secure ground at contact and in the booth and increase the voltage

- adjust the distance between the part and the gun

- increase the distance between parts in the paint booth

- Increase the amount of the recycled powder (if applicable)

- decrease the speed of the line

REASON:

- Powder from the gun is too much

- Distance between gun and part is inadequate

- Spraying gun voltage is too low

- paint line voltage is too high

SOLUTION:

- Adjust the amount of powder from the spray gun and adjust the distance between the part and the gun

- Increase the gun voltage

- control electronic equipment's to decrease the voltage

REASON:

- Air velocity is too high

- Powder from the gun is too less

- Poor or weak grounding

- the amount of recycled powder is too much

- The spray gun and the parts are either too close or too far

- the powder type is not suitable for complex parts

SOLUTION:

- Decrease the air pressure of spray gun

- Adjust amount of powder from the spray gun

- Check and secure ground

- decrease the amount of fresh powder

- Adjust the distance between the gun and the part

- contact the powder manufacturer to produce a powder for complex parts

REASON:

- the metallic color is too much

- The powder is we

- the amount of the recycled powder is too much

- Poor grounding

SOLUTION:

- contact with the powder manufacturer

- clean all powder equipment and use the fresh powder

- control the recycled powder amount

- control grounding

REASON:

- Film thickness is too high

- Powder paint moves to the edges

- Inappropriate curing conditions (Heat-up rate is too high)

- Powder falls and accumulates at the bottom of the part

SOLUTION:

- Decrease the powder from the gun to reduce film thickness

- Check and secure ground and/or decrease the voltage

- Adjust heat up speed. Check the oven and adjust temperature

- Check system parameters

REASON:

- Contamination of powder with other materials and powders of different specifications

- Over curing

- Oil or other contaminants in the oven

SOLUTION:

- Clean the coating booth, spraying gun and hoses properly before replacing with new powder

- Adjust the oven heat

- Check the oven for oils or other materials and clean it

REASON:

- Over or under curing

- High thickness of the part

SOLUTION:

- Increase the temperature and curing time

- Increase dry off oven temperature or the time parts spendش in the dry off oven

REASON:

- Paint booth is not properly cleaned of the previous color causing haziness or variation in color

- Powder is too old or has expired

- Over curing

SOLUTION:

- Clean the booth thoroughly before changing or adding new colors

- consult with powder manufacturer

- decrease the oven temperature

REASON:

- low thickness of the powder

- powder equipment's are rusty

- poor grounding and voltage

- powder has a formulation problem

SOLUTION:

- increase the powder thickness

- change and renew equipment's

- check voltage and grounding

- contact and consult with powder manufacturer

REASON:

- low film thickness

- pain line equipment's or spray gun are worn

- poor grounding

- air compressor contamination with oil and water

SOLUTION:

- increase the film thickness

- repair and renew the equipments

- control grounding

- Clean the coating booth, spraying gun and hoses properly before replacing with new powder

REASON:

- the powder is too coarse

- voltage variation due to the worn parts

- The spray gun and the parts are too close

- The time that a part is being coated is too much

SOLUTION:

- Sift the powder using sieve number 100 microns

- check the voltage and change the spray gun parts

- Adjust the distance between the gun and the part

- increase the paint line speed

REASON:

- high temperature and long curing time

- the powder is combined with other matte colors

- color formulation change

SOLUTION:

- Decrease the temperature and curing time

- clean the hoses and paint line from the previous color

- contact and consult with the powder manufacturer

REASON:

- Oven temperature is too low

- The powder is contaminated with smooth powders in the hopper

- Powder has expired

- high part thickness

- Storage conditions are not favorable

SOLUTION:

- Adjust and increase the oven temperature

- Clean the hopper / paint booth and hoses of other powders

- Check the expiration date

- heat the part before curing

- Check storage conditions (Temp and Humidity)

REASON:

- high film thickness

- over or under curing

- Inadequate or Incompatible cleaning or pretreatment

SOLUTION:

- pay attention to the standard film thickness

- check curing time and temperature based on the data sheet

- Test the washing system and make necessary adjustments (contact supplier)

REASON:

- The UV effect and the environmental condition

SOLUTION:

- For all outdoor parts use polyester (PE) powder instead of Hybrid (MX) colors

REASON:

- The powder is combined and contaminated with other paints

- Poor washing that left oil contaminants on the work piece

- Moisture or oil in compressed air

- High film thickness

- The powder is wet

SOLUTION:

- Clean the paint booth properly before painting and with every color change

- Test the washing system and make necessary adjustments (contact supplier)

- Check the system for oil and moisture

- decrease the film thickness

- Sift the powder and check storage condition

- decrease the film thickness

- Sift the powder and check storage condition

REASON:

- Oven temperature increase quickly

- Film thickness is too low or too high

- curing temperature is low

- poor grounding

- wet or moisture powder

SOLUTION:

- decrease oven temperature

- Measure film thickness with a thickness gauge

- check the data sheet

- decrease paint line temperature before coating

- check the grounding

- contact and consult with the powder manufacturer

REASON:

- combination of the powder with other material and sandtex colors

- Poor washing that left oil contaminants on the work piece

- environmental dust contamination

- Moisture or oil in compressed air

- low thickness of the final surface

SOLUTION:

- clean the hoses and the paint booth

- change and control washing system regularly

- remove dust from paint line environment

- check the compressor air of hoses

- increase the film thickness'

REASON:

- Gun voltage has too much vibration

- poor grounding

- part complexity

- Type of material that is used in the part's metal

SOLUTION:

- Decrease the voltage as much as possible and repair the gun

- check the grounding and clean the hooks

- consult with powder manufacturer and use Tribo colors if possible

- check the material with the part manufacturer

REASON:

- High film thickness

- Powder is wet

- Powder is contaminated with other materials

- Part surface is too rough

- Changes in the process of powder manufacturing

SOLUTION:

- Decrease the paint thickness

- Sift and dry the powder and decrease the ambient temperature of the paint system

- Clean the hopper, paint booth and hoses again

- Modify the cleaning and surface preparing procedure of the part

- Consult with powder manufacturer and follow their recommendations

REASON:

- Inadequate washing and / or poor surface preparation

- Insufficient baking

- Very High film thickness

SOLUTION:

- Test the washing system and make necessary adjustments

- Increase the temperature or baking time

- Adjust paint thickness based on Manufacturer Standard

REASON:

- Oven temperature is too low

- Hammertone colors are combined and contaminated with other colors

- Part thickness is more than 4 millimeter

- The powder is expired

- Poor storage condition

- Recycled powder amount is too much

SOLUTION:

- Oven temperature should be more than 130 C in the beginning

- Clean the paint line from other colors

- heat the part before curing

- check the storage condition

- decrease recycled powder amount and use fresh powder instead

REASON:

- environmental effects, corrosion and human touch

SOLUTION:

- Use transparent clear as top coat for protection

REASON:

- Poor grounding is one of the major reasons of powder problems and final coverage

SOLUTION:

- Clean the hooks regularly

- check the grounding on the part using ohmmeter

- check grounding using cableش

REASON:

- contamination of the air compressor is one of the main reasons of low gloss, pinholes and caraters, low quality of powder, hardening of powder, increase the amount of powder and corrosion of the gun

SOLUTION:

- Installation of dehumidifier and oil filter near the gun and hoses

- Check The inlet air

- spray the outlet air on the mirror