How to spray powder coating

Category: PowderType: Article

1/26/2022

Metal surface preparation

Powder paint is used on any piece that is a conductor of electric current and has the resistance of the desired paint temperature. How to prepare the surface before applying paint in order to increase the mechanical and chemical resistance and the appearance characteristics of painted parts is of particular importance.

The table below shows the optimal infrastructure for different levels:

splash

Fam coating powder colors in different types are applied manually or automatically by Corona or Tribo spraying systems. Cleaning the spray machine and its accessories and the spray chamber in case of changing the color (in terms of color, design, base and even brand used) in order to achieve the desired quality coating is essential in the process of painting parts.

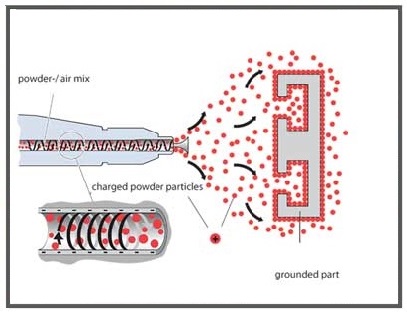

Corona spraying system

In the corona charging method, the voltage difference between the gun and the product charges the powder particles and directs them towards the product to be coated. Adjusting the voltage of the spraying device according to the type of powder paint used in this method is of particular importance.

benefits

- Fast charging of powder particles

- Moving powder particles towards the product with the help of electrostatic field

-Suitable for all kinds of powder colors

- Placement of powder particles of different sizes uniformly

- Ability to change color and wash quickly

- Low depreciation and reduction of repair equipment

- The possibility of changing the thickness of the paint layer with different voltages

Disadvantages

-Decreasing the charging of particles in case of high electrostatic field

-Possibility of skin turning orange due to voltage changes

- Poor coverage in corners and blind spots

Tribo injection system

In the tribo charging method, powder particles are charged as a result of rubbing with the internal surfaces of the electrostatic gun.

benefits

- Possibility of better coverage of corners and edges

- Very uniform and uniform coverage

- Uniform coloring without orange peel

- Better automation equipment

-No need for a voltage generator

Disadvantages

- The color formulation must be adjusted for tribo charging

- Relatively poor efficiency for some electrostatic powders

- Limitation in charging powder particles smaller than 10 microns

- Changing the color and washing is time-consuming and difficult

-Reducing the time and efficiency of charging powder particles in long-term painting operations

- More depreciation and increased replacement of repair equipment

- Due to the need for more time in charging the powder particles, more number of pistols is needed

Baking powder paint

After undercoating and finishing work, paint curing can be mentioned as the main factor to achieve the desired coating and properties. In fact, incomplete baking has an adverse effect on the final coating. The baking temperature of powder colors is usually between 160 and 200 degrees Celsius and it lasts between 10 and 25 minutes. Low baking temperature or short residence time in a suitable oven weakens the mechanical and chemical resistance of the paint film and causes an unfavorable appearance of the paint in certain colors (especially hammers). Baking with high temperature and time longer than the standard also causes matting of glossy colors and change of color of powder coatings.

Tags:

powder coating application