powder coating curing process

Category: PowderType: Article

2/27/2022

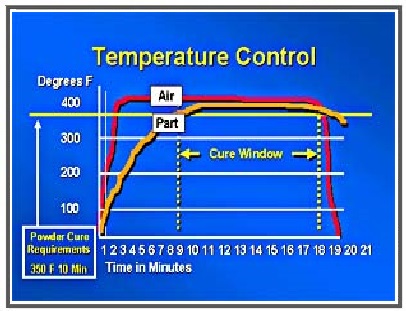

Considering the fact that in the subject of thermo set powder paint, which hardens and forms with heat, the term of paint curing is of vital importance in the matter of chemical and mechanical resistance and the appearance of the final coating, and the awareness of the user of paints Electrostatic powder has double importance in this case.

The following article has technically and briefly answered the questions in this case that each department has methods of monitoring and testing to ensure the baking of the final coating.

How do we know that the powder coating is partially baked?

Using the same method for all purposes can lead to problems such as peeling of the color and inconsistency in appearance. When you come across a new powder coating product, always spray a sample first, it is better to notice the problems when you are working on the sample than when you are spraying on the original piece.

Partial cooking time may cause confusion, how can you know that partial cooking has been achieved? The internet is full of different opinions and ideas that may be right, but at the same time there is also bad advice that may get you into trouble.

So we explain a few things to you:

Partial curing refers to the gelling time of the coating before complete curing. The question here is whether 50% or 70% curing is relative curing. Yes, it is, but so is the coverage that has just been released. Different coatings with different chemistries mean that there is no one-size-fits-all coating method.

When does partial cooking matter?

Partial curing is important when a second coat, such as a full coat, is applied over a base coat. A semi-cured powder allows the two contact layers to bond together both mechanically and chemically, thereby ensuring that the most durable coating possible is achieved.

The general rule for powder coating colors and metallic paints with light particles is that you can take the parts out of the oven a few minutes after the complete flow of the coating. Keep in mind that you don't need to monitor the temperature of the metal part (PMT) for partial curing, you just need to monitor the state of the powder during flow. In fact, it is not necessary to heat the second layer or top coat for proper adhesion of the coating; As soon as the base coat is heated again, it becomes a gel and sticks to the top layer. If the correct program is used for baking the top layer, the two layers will stick together well.

General rule for metallic coatings Fam coating: partial curing is a bit more complicated for coatings that have heavier metallic particles and for them different methods must be used. When the metallic powder paint particles reach the gel state, they move towards the upper coating, so it is important to allow a few minutes of additional time after the powder has flowed so that the metallic particles stabilize. How much extra time they need depends on the thickness of the piece and how fast your oven heats up, lower temperature ovens and thicker pieces need more time. When the topcoat layer gets too hot, the metallic particles may move and shift disproportionately, so we do not recommend this method.

In the above article, it is generally discussed about the baking of powder coatings and hard heat and their liquefaction time, which in the case of Fam coating products, these numbers have been determined and fixed at temperatures with specific quantities. But these values do not necessarily mean that these numerical quantities are general. In case of customer's need, by contacting or writing to the technical unit of the company, the necessary guidance and consultation will be provided.

Tags:

powder coating cure