Hiding, Yield & Efficiency

Category: PowderType: Article

2/8/2022

In general, the transfer efficiency in electrostatic powder paints is very high due to the possibility of its recycling. The amount of coating with powder paints depends on two factors:

Specific weight and size of powder particles.

The coverage amount of the colors produced by Fam coating are as follows:

- Smooth paints with a thickness of 50 to 70 microns, each kilogram of powder on smooth surfaces of 10 to 12 square meters

- Sanding paints with a thickness of 50 to 70 microns, each kilogram of powder on smooth surfaces of 8 to 10 square meters

- Leather paints with a thickness of 80 to 100 microns, each kilogram of powder on smooth surfaces of 6 to 8 square meters.

- Hammer paints with a thickness of 90 to 120 microns, each kilogram of powder on smooth surfaces of 6 to 8 square meters.

Note: The above measurements are obtained by taking into account the consumption of recycling and on smooth surfaces in laboratory calculations, and they naturally change on surfaces with angles and complexity. Meanwhile, by referring to the page of calculating the surface coverage of the part, you can more accurately calculate the amount of powder Calculate your need.

Efficiency of color application on the part

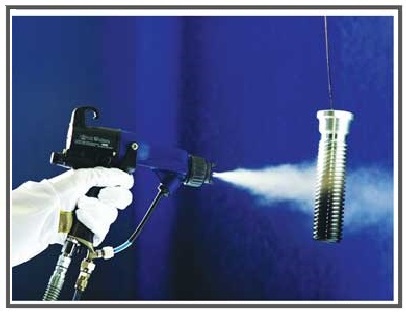

When spraying powder by electrostatic gun, some of it sticks on the surface of the part and some falls to the ground. The percentage ratio of the amount that is stuck and the amount that is wasted is the spraying efficiency.

Air pressure and speed in the gun

Excessive air speed reduces the efficiency and collects powder in the corners. The powder particles are directed towards the piece by the air flow and stick to the piece with the help of electrostatic attraction. If the movement of particles towards the part is too fast. The powder particles hit the piece hard and due to the high energy of the air, they don't have a chance to stick to the piece and fall to the ground. In general, the lower the air speed, the higher the adhesion efficiency and the less waste.

The distance of the rifle (pistol) from the piece

If the distance of the gun is more than allowed, the powder particles from the side of the piece due to low energy will not adhere to the surface and fall to the ground. On the other hand, if the distance is too short, due to the decrease in voltage and the increase in amperage in short distances, the powder paint will be charged more than allowed and will cause it to run away, peel back, or turn the surface orange. The ideal distance for experimentally painting parts for hand guns is about 15 to 20 cm.

Use a suitable spray nozzle

Powder spray guns can be equipped with different types of nozzles. Female corner (blade) nozzles have a larger spray width and a higher speed of powder particle transfer. These types of nozzles generally have more waste and are suitable for spraying heavy colors such as metallic, hammered, leather and patterned. Dusting nozzles (plates) can be used as a standard in most cases. These types of nozzles are available in different dimensions and sizes. It is suggested to try the nozzles depending on their shape and size to get the best result.

Negative effects of humidity and heat

Heat and humidity have very noticeable effects on the quality of the paint layer. Any change of these two factors directly affects the flow of powder in the gun, production efficiency, life of cabin filters and electric charge of the powder.

High heat causes a change in the chemical/physical properties of the powder, and an increase in humidity causes it to clot. On the other hand, very dry air also causes a noticeable reduction in the ability of electrical charging and coating.

Therefore, it is suggested to set the relative humidity of the environment around 50-60 degrees and its heat around 25 degrees Celsius.

earth

One of the most important things in electrostatic powder coating is paying attention to the correct grounding of the piece. If the ground connection is broken or weak, consumption will increase, the powder will not stick to the surface, causing other risks such as powder recoil, sparking, and the like. The electrical resistance value between the component and the earth well should always be less than 1 megaohm (1 million ohms).

Powder particle size and granulation

Granulation of powder particles and its size directly affects the quality of the paint layer and the volume of waste.

Very soft granulation causes poor movement of powder in the gun and pump and causes a noticeable reduction in electric charge and increase in powder roundness, waste and cost. On the other hand, the coarse granulation of the powder causes an increase in weight, the paint does not stick to the part and it spills on the cabin floor, and in high voltages, it causes the Faraday cage challenge.

Therefore, it should be noted that the granulation of powder particles is always within the standard range, neither too fine nor coarse.

In general, all cheap powders have large and non-standard granulations and high specific weight due to technical problems in their production. These types of powders have very low coverage and a lot of waste, and finally, despite their low price, at the time of purchase, after the final calculation, they end up being more expensive than standard and high quality powders.

The ratio of recycled paint to new paint

The most important advantage of powder paints is the possibility of recycling. If we assume that the amount of powder paint in the filters and on the hangers is insignificant, about 95% of the paint is recycled and re-enters the production cycle. In order to obtain the amount of recycled paint, the amount of transfer efficiency should be determined first. It is obvious that the color transfer efficiency is proportional to the color application method and maintenance of spraying equipment (gun-nozzle-hose) and earth connection.

A weak earth connection causes a significant reduction in transmission efficiency.

Tags:

Hiding Yield Efficiency